Comprehensive services from A to Z

Comprehensive Solutions for Your Aluminum Foundry

We do more than supply products. We design, manufacture, and install complete casting systems tailored precisely to your operational requirements. With Keramservis, you gain a partner who will guide you through the entire process — from initial consultation and engineering design to installation and maintenance training.

Material Data SheetsDESIGN AND CONSULTATION

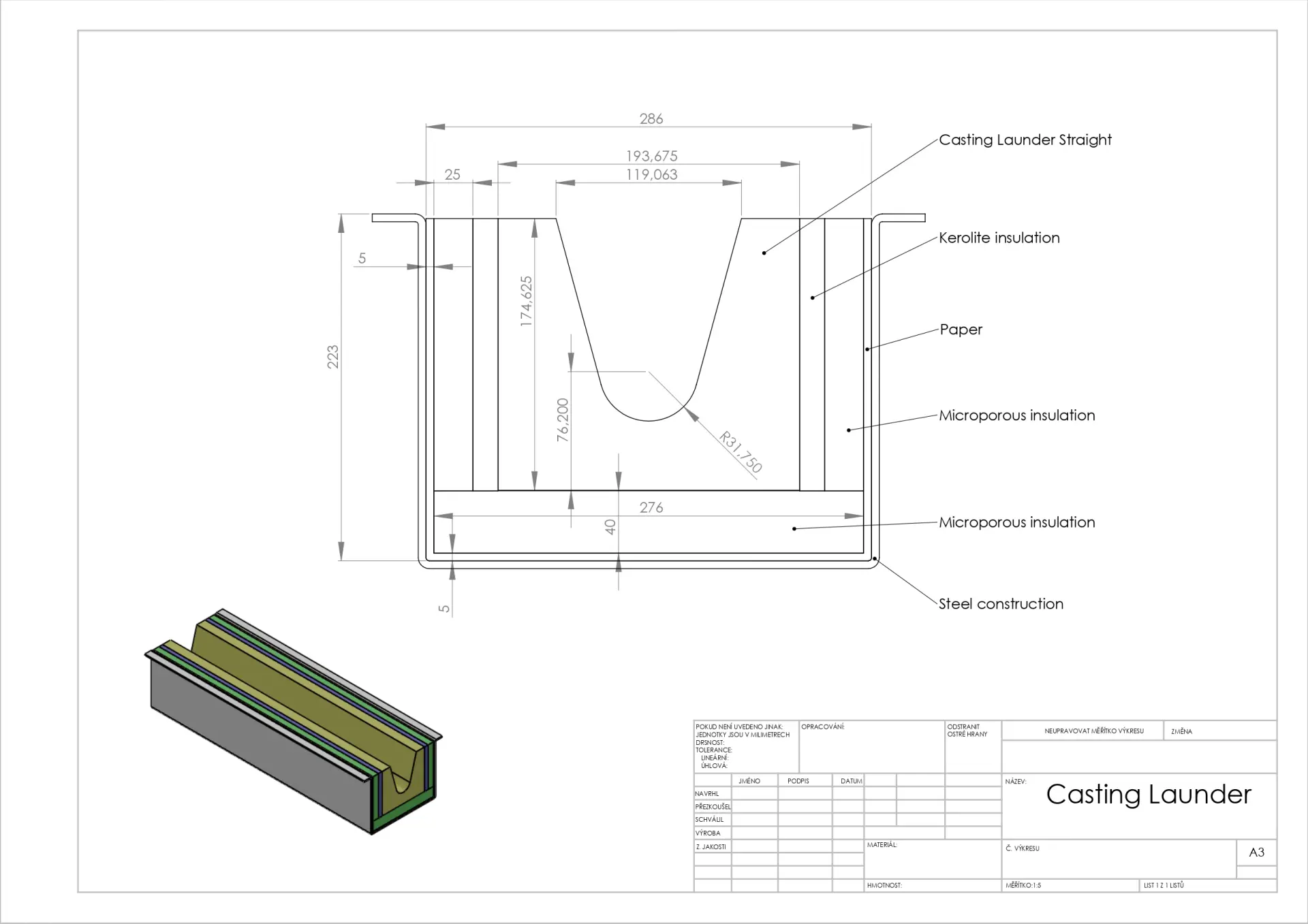

Design of casting line dimensions and geometries between the melting furnace, holding furnace, and casting equipment.

We design the optimal configuration of the casting line between the melting furnace, holding furnace, and casting equipment, taking into account the specifics of your operation, metal flow dynamics, and performance requirements.

Analysis of your operational needs and existing systems

Optimal layout design of casting lines

Calculation of metal flow rates and thermal losses

SELECTION OF MATERIALS AND COMPONENTS

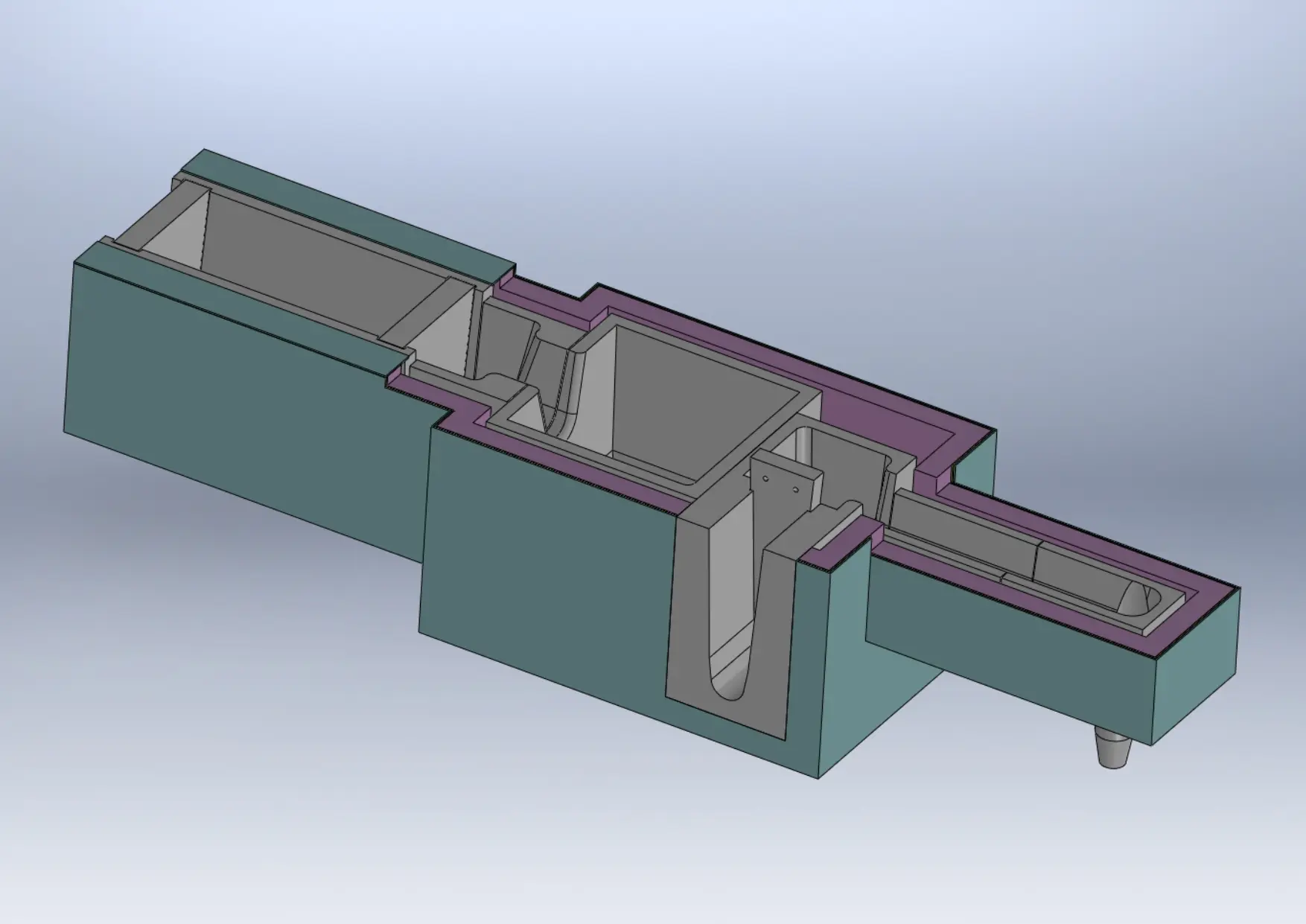

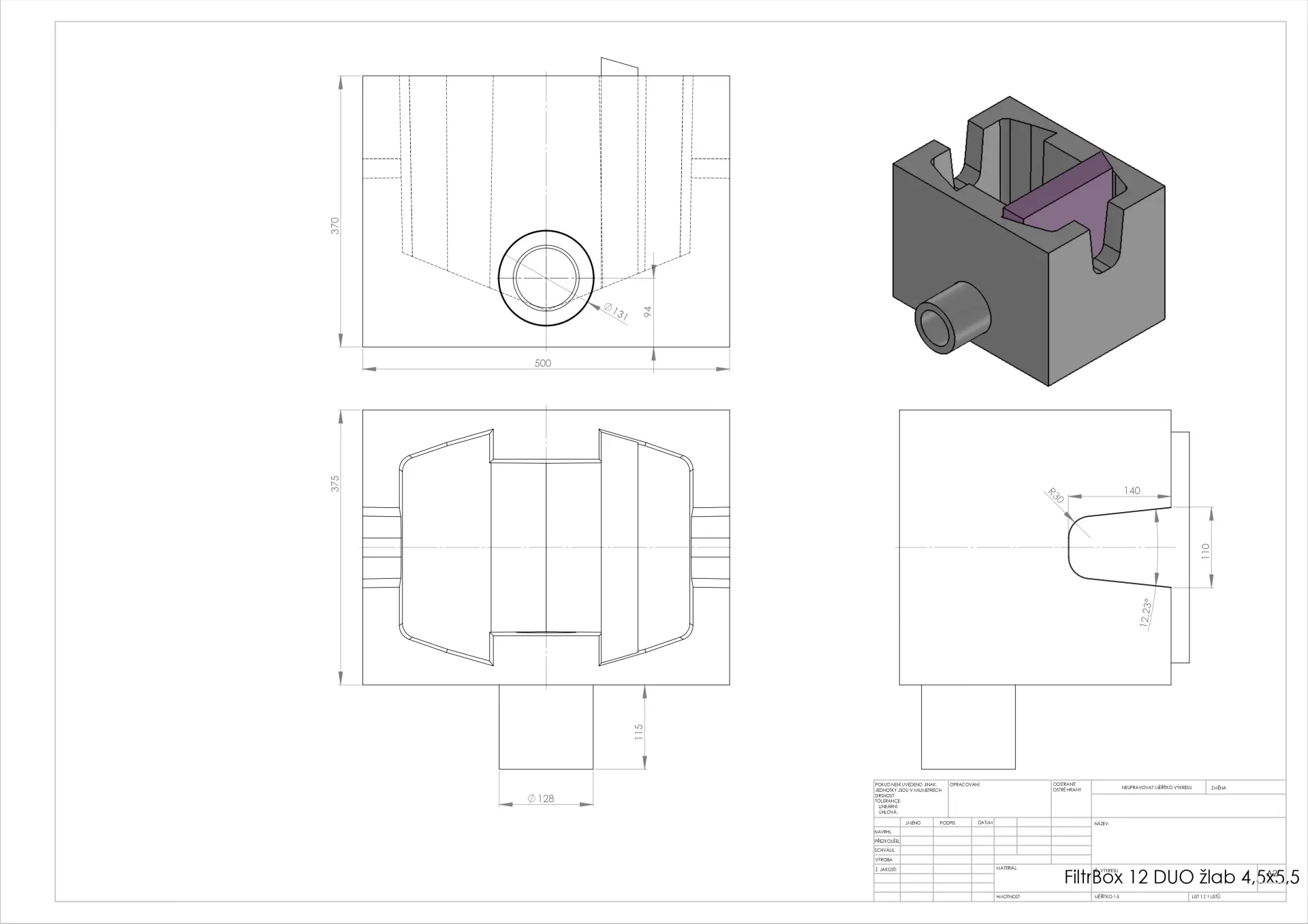

Design and specification of materials, dimensions, and cross-sections of individual casting line components (launders, filtration boxes, degassing boxes, casting nozzles, dams, etc.).

We select the appropriate materials and components based on thermal stress, mechanical load, and chemical exposure in each section of the casting system.

Ceramic launders (SILKON 150/220/270)

Filter boxes

Degassing boxes

Stoppers and regulation elements

INSULATION AND MOUNTING

Design of insulation systems and mounting of individual refractory components within the steel structure.

We ensure optimal thermal insulation and secure mounting of all components to minimize heat loss and maximize service life.

Insulation system design

Selection of insulating materials

Dimensioning of insulation boards

CUSTOM MANUFACTURING

Manufacturing of engineered refractory components.

All components are manufactured precisely according to the approved design. Our in-house production facilities ensure full quality control and manufacturing flexibility.

Proprietary SILKON mixtures

Precise shape execution

Atypical custom shapes

INSTALLATION

Installation of engineered casting systems directly at your facility.

Our technicians perform complete installation of the casting system on-site, ensuring correct mounting, insulation, alignment, and operational testing.

Installation of all ceramic components

Application of insulating materials

Production and supply of maintenance materials including operator training.

MAINTENANCE AND TRAINING

Maintenance training including the production and supply of maintenance materials.

All maintenance components and materials are manufactured according to approved designs, with full in-house production control and quality assurance.

Practical maintenance training

Manuals and documentation

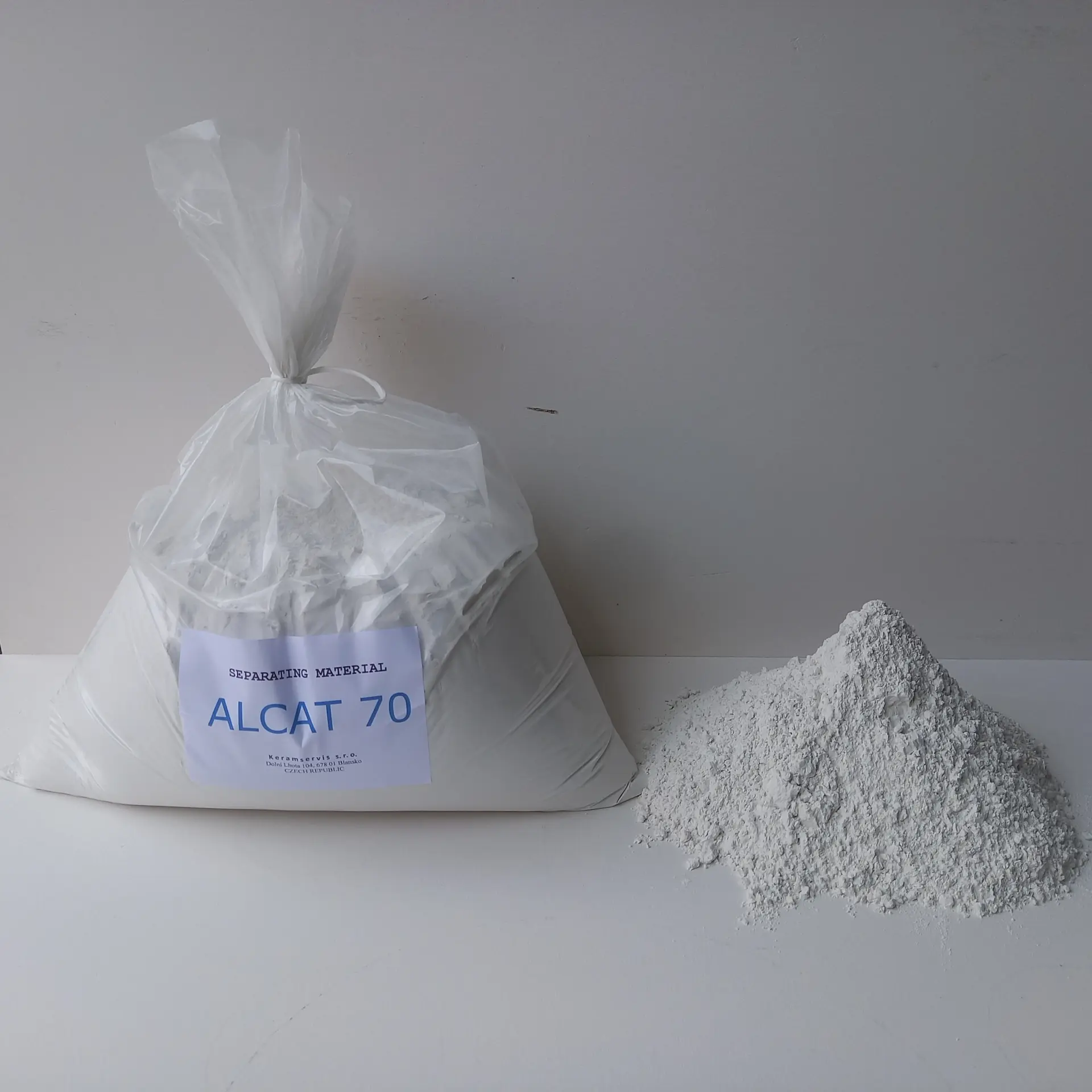

Supply of protective coatings

Supply of topping/covering mixtures

💡 Learning from Practice

A key element of our work is long-term customer feedback. We continuously evaluate the service life of critical components in relation to specific operating conditions.

Material optimization proposals

Component dimensioning

Preventive maintenance strategies